Boring & Facing

Company Overview

D’ANDREA is an Italian company, world leader in the manufacture of high precision machine tool accessories. Known worldwide for the quality of its products, D’ANDREA has been developing increasingly effective technologies since 1951, keeping pace with the modern demands of the precision engineering industry. The entire D’ANDREA range comes from its headquarters in Lainate, just outside Milan: TA-CENTER, TA-TRONIC, U-TRONIC, U-COMAX and AUTORADIAL facing and boring heads. The high precision modular tool holder system MODULHARD’ANDREA and the complete balanceable toolholder system for high-speed applications TOPRUN, MONOd', MONOforce and MCD'.

Modular Boring System

Arbor Extension Reduction

Arbors are manufactured in DIN 69871, MAS 403 BT, DIN 2080, ANSI-CAT, HSK, PSC and are made of carburized steel, hardened and ground to AT3 tolerance.

Extensions of various lengths are available for each MHD’ size, which make it possible to optimize the desired machining depth.

MHD’ components of a smaller size can be used by means of adaptor sleeves which allow greater interchangeability and ensure tool stability.

Carbide Bar

Carbide bars for deep-hole machining. D’Andrea solves the deep-hole boring machining by means of a wide program of BMD carbide bars having diameter 16, 20, 25, 32 mm diameter and ending with MHD’ arbor.

Chucking Tools

The complete program of D’Andrea modular adapters with MHD connection, satisfies the various processing needs related to milling, drilling, and tapping. Available with output of collect chuck, side lock, face mill, Morse taper, drill chuck and through coolant system.

Double Bit Heads

The double-bit heads are easy and extremely rigid thanks to the extensive serrated areas in contact between the bit holder seats and the heads, together with the constant distance between the seat clamping screw and the cutter. Two bit holders are used for roughing operations involving heavy chip removal.

Double Bit Boring Crossbar

The BPS double-bit crossbars cover a working area from ø 200 - 2800 mm. The BPS double-bit crossbars are constructed in aluminum and mounted on a steel double-bit plate.

TRD: Combination Boring Head

The double-bit TRD heads allow both roughing and high precision finish thanks to their rigidity and the sensitivity of the sliding mechanism which can achieve radial correction of 5 microns. This can be carried out directly on the machine and easily read on the vernier scale. Diameter: Max.: 160 mm | Min.: 28 mm

TRC Heads (L.C: 10 micron)

High precision work to IT6 tolerance, with excellent surface finish, is achieved using TRC boring heads. These are very sensitive and radial correction of 10 microns can be effected directly on the machine and easily read on the vernier scale. Diameter - max 200 mm I min 2.5 mm

TRM Heads (L.C: 2 micron)

The TRM heads in the D’Andrea Testarossa line have a protective rustproof coating. High precision work to IT6 tolerance, with excellent surface finish, is achieved using TRM boring heads. These are very sensitive and radial correction of 1 micron can be effected directly on the machine and easily read on the vernier scale. Diameter - max 500 I min 2.5 mm

Boring Kits

The Testarossa kits are supplied in a box with a wide range of tool holders, tools, inserts and service spanners. Kits are available in range of Ø 6-110, Ø 6-125 & Ø 6 -220

TR Elettra (Digital) Heads

The TR-Elettra is a finishing head, where the radial displacement of the tool holder slide is viewed on a built-in digital display, providing the operator with maximum speed and accuracy of adjustment. The operating range of these heads is extensive: from 2.5 mm to 2,700 mm depending on the size of the head selected. The TR-Elettra is the digital evolution of the TRM, the famous D’ANDREA micrometre finishing head

NC Facing Head

TA-CENTER

TA-CENTER boring and facing heads are made to be used on machines with automatic tool change, therefore on essentially all machining centers. A U-Drive unit commands the feed control of the tool slide and the tool placement even during rotation.

This unit is managed directly by an axis called “U” by the machining center NC to perform different processes like inner and outer turning operations, grooves, conical and variable boring, concave and convex corner rounding, cylindrical and conical threading, phonographic grooves and spherical machining. TA-Center heads are constructed in 7 models from TA-C 80 to TA-C300.

TA-TRONIC

TA-Tronic boring and facing heads can be manually or automatically applied on small boring machines, machining centers and special machines.

Two possibilities are available for the control unit of the TA-Tronic head: - The first one involves a direct connection to the “U” axis of the NC in the machine tool which allows boring, inner facing, outer facing, back–facing, grooving, phonographic grooves, threading and taper boring, taper and variable boring, concave and convex corner rounding through interpolation with the other axis. - The second with a simple and economical U-CONTROL positioner with a wireless REMOTE-CONTROL. The positioner can be connected to the M functions of the machine to receive start signals of the various operations programmed on the REMOTE-CONTROL. This solution allows boring machining, inner facing, outer facing, back-facing, inner and outer turning operations, grooves, phonographic grooves, threading, and taper boring. Spherical machining is not possible with machines equipped with the U-CONTROL WIRELESS KIT

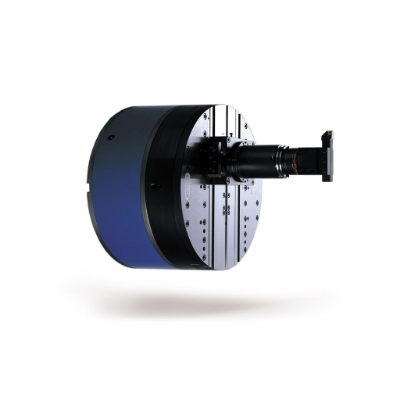

U-TRONIC

U-TRONIC are medium and large sized NC heads that are connected to the U axis of the NC in the machine tool for outer facing, inner facing, back-facing, cylindrical and conical boring and threading, concave and convex corner rounding through interpolation with the other axes of the machine tool. They can be applied manually or automatically and with pallet systems on boring machines, machining centres and special machines. They are constructed in 6 models from ø 360 to ø 1000 mm.

U COMAX

U-Comax boring and facing heads are axial command heads designed to be used on transfer machines, machining units, and special machinery.

Even during rotation the feed control of the toolholder slide is commanded by a U-Drive drive unit, mounted behind the spindle and managed directly by the NC of the machine tool. U-Comax heads are used for inner facing, outer facing, back-facing, inner and outer turning operations, grooves, phonographic grooves, cylindrical and conical threading, conical and variable boring, concave and convex corner rounding, through interpolation with the other the machine axes.

AUTORADIAL

The AUTORADIAL heads are applicable on machining centers and on N.C. machines and, without the need of any electronic interface, they can automatically execute a working cycle of facing, back facing, internal or external grooving for spring washers and O-rings, phonographic groove cutting on flanges. The cycle is composed of the working feed and of the quick return of the slide without ever stopping or reversing the rotation of the spindle.