Tool Presetting

Company Overview

NIKKEN KOSAKUSHO WORKS LIMITED, the industry leader in the manufacture and distribution of advanced Tool Holding Systems, CNC Rotary Tables and accessories and ELBO CONTROLLI SRL, a major player in the fields of Tool Presetting, Inspection and Tool Management Systems, are delighted to announce that they have now commenced a new global Strategic Alliance. Both companies have a long-standing synergy and this strengthened relationship allows the two technology partners to innovate and move forward both their products and solutions ‘Closer Together’

Presetters

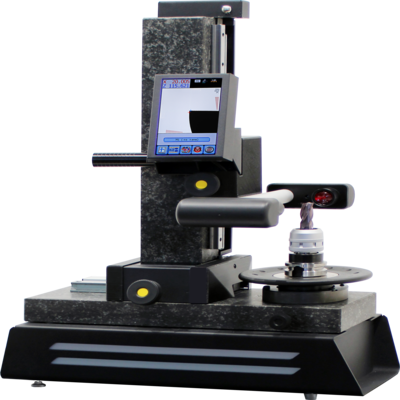

Larth

-

Mechanics

- Measuring Range: Diameter max 260 mm (radius 130 mm); height max 360 mm

- Base and column made of ground granite

- ISO/BT/HSK/VDI etc. Interchangeable rotating spindle holder

- 4 Re-circulating ball bearing linear slides

- Manual mechanical braking of the interchangeable spindle- holder Rotation

- Manual axes movement

- Overall dimensions: L=570 mm, H=793 mm, D=408 mm

- Net Weight: 45 Kg

- Electronics - Optics

- Vision system for tool measuring

- Elbo Controlli Nikken linear transducers in optical glass type slide 371

- Axes resolution: X=1μm, Z=1μm

- C-MOS sensor framed image area 5 X 5 mm

- 20x magnification

- Telecentric lens and led illuminator

- TFT colour LCD 7" led backlight points matrix graphic display (86 X 150 mm image size)

- Full touch-screen for all presetter operations

- Elbo Controlli Nikken firmware

- Data storage on flash memory

- Electronics driver based on RISC 32 bit processor and integrated vision system

- Software

- 9 Numerical machine origin management

- 9 Numerical tool tables management, each of them composed of 99 tools

- Tool corrector specific storage of T, Lx, Lz, insert radius

- Intuitive icons and menu-based software

- Display radius/diameter, mm/inch, abs/inc

- Measurement capability by full-screen auto-targeting

- X axis and Z axis focusing control bars

- Radius and angle automatic computing cycle

- TD2361 to manage backup and restore functions, machine origins and tool tables. Connection to the PC with an USB port and electronic bios upgrade

- Optional

- Label Printer

- Machine stand

E346

- Measuring range: diameter max 360 mm (radius 180mm); height max 460 mm

- Base and column made of NATURAL GRANITE: linearity max error 2 μm/m

- Machine structure in electro-welded and detensioned steel

- ISO/BT/HSK/CAPTO... etc. interchangeable rotating spindle holder (to be specified) max run-out error < 4 µm

- Double vault arc prismatic slideways: N°2 X axis slideways; N°1 Z axis slideway

- Double re-circulating ball bearing slides, lubrificated for life (3) (preloaded slides/ slideways: P/H class)

- Manual mechanical braking of the interchangeable spindle - holder rotation

- VACUUM clamping system (E346V+)

- Vision-system for tool measuring including:

- C-MOS sensor-framed image area 6,4 x 6,4 mm

- Magnifications 25X

- Cutting inspection

- Machine operator interface through:

- TFT 15" colour 16:9 vertical Touch Screen monitor

- Intel Celeron N Series 4 Core

- UBUNTU LINUX operating system

- Data storage on solid state disk SSD

- Software standard:

- CNC machine origin management and adapters

- Tool list creation and/or single tool

- Tools set and Post Processor universal generator

- magnetic chip code-holders (Balluff for example,hardware not included)

- printable tool set report

- theoretical measurements and tolerances management

- Analog comparators to measure on the fix reticule

- Telecentric lens and LED illuminator

- Axes resolution: X = 1 μm, Z = 1 μm

- TID (Automatic Tool Identification System) ready

Sethy Six

- Base & column made of natural granite and machine structure in stainless steel.

- ISO/BT/HSK/CAPTO/VDI interchangeable spindle. Max run out ≤ 4µ

- Measuring range dia400 mm & height 600 mm.

- C-MOS sensor - Framed image area 6.4 x 6.4 mm.

- TFT 15" colour Touch Screen& Magnifications 30X.

- Measurement capability by digital comparator, auto-targeting and auto freezing.

- TOOLINGUP to manage tools set and Post Processor universal generator, magnetic chip code-holder and multi-cutting tools.

Hathor Six/A

- Base & column made of natural granite and machine structure in stainless steel.

- ISO/BT/HSK/CAPTO/VDI interchangeable spindle and run out ≤ 2µ

- Measuring range dia400 mm & height 600 mm with 0.001 measuring resolution.

- Universal mechanical tool clamping (ISO/BT only)and pneumatic braking.

- C-MOS sensor - Framed image area 6.4 x 6.4 mm.

- TFT 15" colour Touch Screen& Magnifications 30X.

- SP-ID function and Autofocusing measurement optional.

- Td SIX to managetools set and Post Processor universal generator,magnetic chip code-holder and printable tool set report.

E46L/A

- Base & column made of natural granite and interchangeable spindle.

- Measuring range dia400 mm & height 600 mm with 0.001 measuring resolution.

- Universal mechanical tool clamping (ISO/BT only)and pneumatic braking.

- C-MOS sensor - Framed image area 10 x 10 mm.

- Full HD LCD 22” colour Touch-Screen monitor& Magnifications 26X.

- Tool profile acquisition exportable in DXF format and import capability.

- SP-ID function and Autofocusing measurement optional.

- TLA technology (Tool Link App) for tool data transmission directly to numerical control memory (DNC)

E46 LTW/A

- Base & column made of natural granite and interchangeable spindle.

- Measuring range dia320 mm & height 600 mm with 0.001 measuring resolution.

- Universal mechanical tool clamping (ISO/BT only)and pneumatic braking.

- Main camera C-MOS sensor 1.3 Mega pixelsMagnification 26X, digital zoom 2X and 4X available.

- 2nd/3rd camera C-MOS sensor 1.3 Mega pixels Magnification 60X, digital zoom 2X and 4X available.

- SP-ID function and Autofocusing measurement optional.

- TLA technology (Tool Link App) for tool data transmission directly to numerical control memory (DNC)

E68B/A

- Base & column made of natural granite and interchangeable spindle.

- Measuring range dia600 mm & height 800 mm with 0.001 measuring resolution.

- Universal mechanical tool clamping (ISO/BT only) and pneumatic braking.

- Motorized axes movements. Control panel with micrometric handwheels and rapid movement buttons.

- C-MOS sensor - Framed image area 5 x 5 mm&magnifications38X

- TFT 15" colour Touch Screen monitor with UBUNTU LINUX LTS operating system

- SP-ID function and Autofocusing measurement optional.

- Td SIX to managetools set and Post Processor universal generator,magnetic chip Code-holder and printable tool set report.

E68L

- Base & column made of natural granite and interchangeable spindle.

- Measuring range dia600 mm & height 800 mm with 0.001 measuring resolution.

- Universal mechanical tool clamping (ISO/BT only) and pneumatic braking.

- Motorized axes movements. Control panel with micrometric handwheels and rapid movement buttons.

- C-MOS sensor - Framed image area 8 x 8 mm & magnifications 38X

- Full HD TFT 22" Touch Screen vertical monitorwith Intel Quad Core processor

- Tool profile acquisition exportable in DXF format and import capability.

- Td SIX to managetools set and Post Processor universal generator, magnetic chip Code -holder and printable tool set report.

E68LA

- Base & column made of natural granite and interchangeable spindle.

- Measuring range dia600 mm & height 800 mm with 0.001measuring resolution.

- Universal mechanical tool clamping (ISO/BT only) and pneumatic braking.

- Motorized axes movements. Control panel with micrometric handwheels and rapid movement buttons.

- SP-ID function and Autofocusing measurement

- C-MOS sensor - Framed image area 8 x 8 mm & magnifications 38X

- Full HD TFT 22" Touch Screen vertical monitorwith Intel Quad Core processor

- Tool profile acquisition exportable in DXF format and import capability.

- Td SIX to managetools set and Post Processor universal generator, magnetic chip Code -holder and printable tool set report.

Softwares

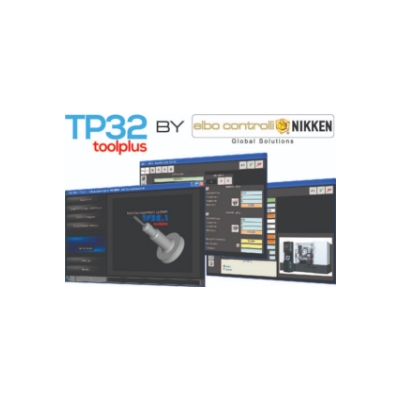

TP32 Tool Management Identification System

TP 32 is a program dedicated to the management of the tool repository woven in as a fundamental component of the productive cycle and as such inserted in a system in which information must be accessible to people and presented in a simplest manner.

TID (Tool Identification Manager System)

TID application is born from the need to have an instrument that allows creating, easily and at a reasonable price, a tool identification system interface with: - tool presetter unit - machine tool NC (FANUC, HEIDENHAIN, MAZAK, SIEMENS, MAKINO, OKUMA and more)

Pulling Force Meter

Pulling Force Meter

he PFM is a measuring instrument that allows, in a simple and quick way, the measurement of both machine tool and presetting machine spindle clamping force. Thanks to its interchangeable adapters, it can measure the pulling force for ISO/BT, SK, ASME, BIG+ PLUS, NIKKEN 3LOCK 40/50. The kg measures have an approximate 3% tolerance. Accuracy and repeatability depend on employment conditions and correct positioning in the machine spindle.